We encounter plastics every day in our daily lives. Many everyday objects are made of plastic, even those you would not expect. Materials such as aluminium or metal often reach their limits, because they cause a higher weight and prevent flexible use. Flexibility is also becoming increasingly important in industrial processing, as is a lower final weight.

Plastics consist mainly of macromolecules and are processed into moulded parts, semi-finished products, films or fibres. They are characterised by technical properties such as hardness, breaking strength, mouldability, elasticity, temperature, heat and chemical resistance. The expression of these characteristics can be varied by the choice of macromolecules, the manufacturing process and by mixing in so-called additives.

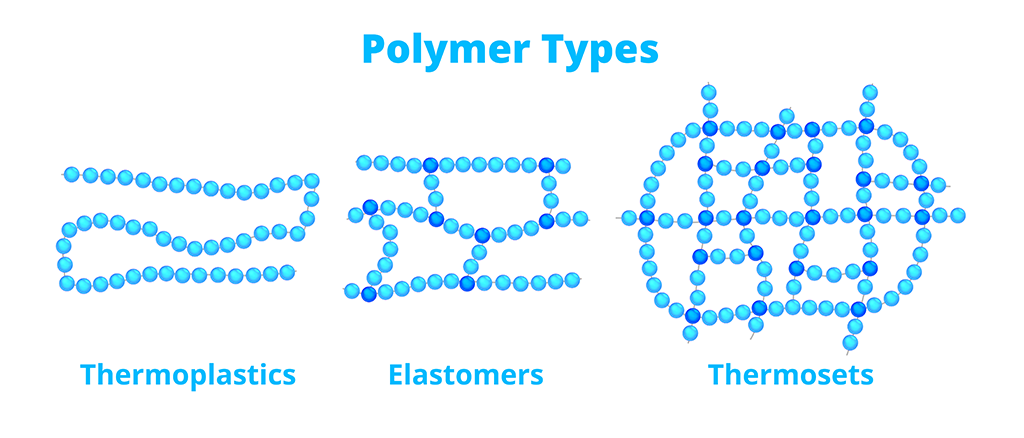

Plastics are classified into three types with regard to their physical properties: Thermoplastics, Thermosets as well as Elastomers. The choice of the appropriate polymer depends on factors such as load, temperature, cost and chemical properties.

Thermoplastics (thermo= warm, hot and “plast” from the ancient Greek plássein = to form, shape), also called plastomers, are plastics that can be deformed by heating in a certain temperature range (thermoplastic). This process is reversible and can be repeated as often as desired by cooling and reheating, as long as no thermal decomposition of the material occurs.

They can be easily injection moulded, cast, extruded and thermoformed, which reduces processing costs and speeds up production. Examples of thermoplastics are polyethylene, polypropylene and polyvinyl chloride (PVC). They are used in a wide range of applications, e.g. in leisure and sports equipment, but also in the automotive and aerospace industries. Thermoplastics have good chemical resistance and are usually resistant to acids, alkalis, solvents and oils. This makes them ideal for applications that are exposed to high chemical stresses. Thermoplastics also have good electrical and thermal insulation properties, which makes them particularly suitable for the manufacture of electrical and electronic devices and cables. Another property that thermoplastics have over other plastics is their weldability: thermoplastics can be welded. Thermoplastics can be welded by heating them until they are soft and malleable and then pressing the parts to be joined together. In the process, the molecules mix at the cut surfaces and join together when they cool and solidify. This process is called thermoplastic welding and is a simple and inexpensive method of joining parts made of thermoplastics. There are different types of thermoplastic welding, e.g. ultrasonic welding, resistance welding and hot air welding.

Unlike thermoset plastics, which cannot be processed repeatedly due to their cross-linked polymer chains, thermoplastics can simply be melted down during recycling.

This means that old products can be processed into new products without changing the material properties. In addition, impurities can be easily removed when recycling thermoplastics.

Overall, the recycling of thermoplastics therefore offers both ecological and economic advantages. It contributes to waste avoidance and resource conservation and helps to reduce the need for fossil raw materials and CO2 emissions.

Thermoplastics are found in a wide range of applications and products in everyday life:

These are just a few examples, but thermoplastics are used in a wide range of industries because of their versatility, lightness, water resistance and durability.

Thermosets are also called duromers or thermosets and are plastics that retain their state and shape after curing. This is because their polymers are spatially cross-linked and can therefore no longer be dissolved. Thermosets are used in electrical installations, among other things, because of their mechanical and chemical resistance even at elevated temperatures. The thermosets that have been processed the longest and most frequently are phenoplastics. Polyester resins, polyurethane resins for lacquers and surface coatings as well as practically all synthetic resins such as epoxy resins also belong to the thermosets.

Elastomers are polymer materials that have a high degree of stretchability and elasticity. They can return to their original shape after being deformed. Their glass transition point is below room temperature. This property makes them ideal for applications such as seals, springs, rubber bands and tyres.

Elastomers are produced in different types, such as rubber, polyurethanes and silicones. Rubber is a natural elastomer derived from rubber tree sap. Polyurethanes and silicones are synthetic elastomers used in a variety of applications, including medical, automotive and construction.

Elastomers also have good resistance to weathering and ageing. They are resistant to water, oils, acids and alkalis. They can also work in a wide range of temperatures, from very low to very high temperatures.

Some disadvantages of elastomers are that they are inferior to other materials in terms of strength and hardness, and they are difficult to machine and recycle.