Discover the wide range of applications for thermoplastic composites in industries. Learn more about the benefits of these innovative materials.

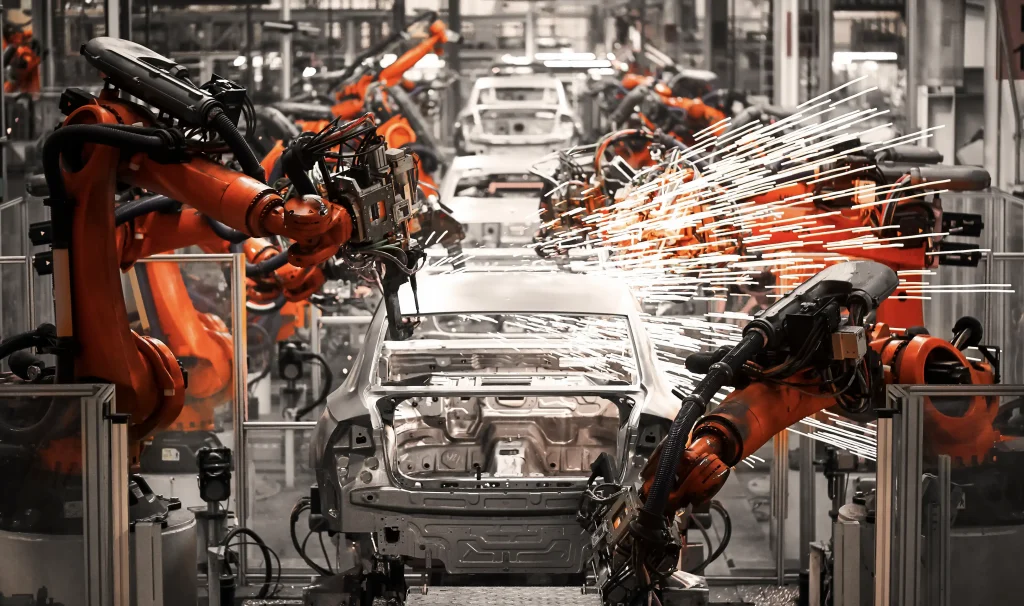

Long and continuous fibre-reinforced thermoplastics are high-performance composites and are increasingly used as lightweight materials in the automotive industry.

The use of 100 kilograms of plastic can – depending on the application – replace about 200 to 300 kilograms of conventional materials such as steel.

This has a positive effect on the climate balance: Lighter cars consume less fuel and thus emit less CO2. Electrically powered vehicles require smaller motors and batteries.

And thermoplastics are also convincing when it comes to processing: they can be injection moulded or thermoformed into almost any shape. In addition, they are among those plastics that can be welded, that bond well and that can be easily recycled.

Thermoplastics are used in many different applications in the automotive industry. These materials offer a number of advantages such as high strength and stiffness, low weight, good heat resistance and high chemical resistance.

Unidirectional tapes are continuous fibre-reinforced tapes that are very thin yet have very high strength and stiffness. Since they are also very light, they are ideal for lightweight construction. UD tapes are also a good choice for the production of complex components. These tapes are ideal for use in the automotive sector because they can also be processed in hybrid moulding or overmoulding and are also flame retardant in certain material combinations.

Fibre-reinforced laminates are used in the automotive industry for various applications, especially for structural components that need to be lightweight yet strong. Some of the most common types of fibre composites used in the automotive industry are:

Carbon fibre reinforced plastics (CFRP): These materials consist of carbon fibres embedded in a plastic matrix. They offer high stiffness and strength with low weight and are often used in high-performance vehicles and racing cars.

Glass fibre reinforced plastics (GRP): These materials consist of glass fibres embedded in a plastic matrix. They are more cost-effective than CFRP and still provide sufficient stiffness and strength for structural applications such as body panels and interior trim.

Natural fibre reinforced plastics (NFRPs): These materials consist of natural fibres such as flax or hemp embedded in a plastic matrix. They are more environmentally friendly than carbon or glass fibre reinforced plastics and can be used in applications such as door panels, dashboards and seat shells.

Aramid fibre reinforced plastics (AFK): These materials consist of aramid fibre embedded in a plastic matrix. They offer high strength and stiffness, as well as excellent resistance to heat and chemicals, and are commonly used in structural components such as frames and beams.

In the automotive industry, LFTs are used in a wide range of applications, including structural components such as door modules, bumpers, body panels, dashboards and seat shells. LFTs are also capable of forming complex shapes and allow for improved design flexibility and production efficiency.

Another advantage of LFTs is their sustainability. They are easy to recycle and generate less waste and emissions during production than other materials.

Overall, long-fibre reinforced thermoplastics offer the automotive industry a wide range of benefits such as high strength and stiffness, low weight and sustainable properties, as well as improved design flexibility and manufacturing efficiency. They are therefore increasingly used as an alternative to other materials and represent a promising option for future developments in the automotive industry.

In the sporting goods industry, mainly thermoplastic composites are used, which consist of a combination of thermoplastic polymer matrices and long-fibre reinforced fibres. Examples of such materials are polyethylene terephthalate (PET), polyamides (PA) and polypropylene (PP) in combination with carbon fibres or glass fibres.

Optimising the performance of sports articles by choosing the right thermoplastic composite material

It should be noted that the choice of thermoplastic composite and the type of fibre reinforcement depends on the requirements of the specific sports article and the desired properties. Thermoplastic composites make it possible to optimise the performance of sports articles. For example, the flexibility of a racket can be adjusted by choosing the right type of fibre and the arrangement of the fibres in the material. Vibration damping can also be optimised by choosing the right thermoplastic material. Compared to classic materials such as wood or aluminium, they are lighter, more stable and more resistant to damage. In addition, they can be used to produce very precise shapes.

Another advantage of thermoplastic composites is that they are recyclable. Unlike conventional materials such as wood or aluminium, thermoplastic composites can simply be melted down again and processed into new products.

Wide range of applications

In the sporting goods industry, thermoplastic composites are used in a variety of applications, including:

Thermoplastic composites have gained importance in construction in recent years because they offer many advantages over traditional materials such as steel and concrete. They are lightweight, strong, corrosion-resistant and durable. They are also easy to process, which shortens construction time and reduces construction costs.

The following thermoplastic composites are mainly used in the construction industry:

Overall, thermoplastic composites are a promising choice for use in construction due to their lightness, strength and weather resistance. However, further research and development can help minimise their disadvantages and further promote their use in future projects.

The future of thermoplastic composites in construction is promising. Their use is expected to continue to increase in the coming years, especially in applications where lightness, durability and resistance to environmental influences are important.

Examples of future applications of thermoplastic composites in construction are: