There are different methods for processing thermoplastic composites. The processing techniques for thermoplastic composites differ depending on their properties and areas of application. For long fiber reinforced thermoplastics, processors use injection molding or extrusion. UD tapes can be processed by thermoforming, tape laying or tape winding. The processing methods are described in more detail below.

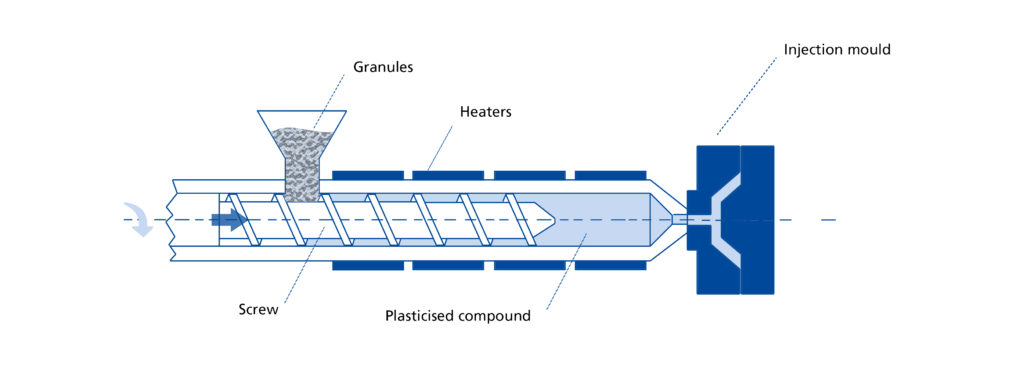

Injection moulding is used in plastics processing and is a form procedures. This process allows an almost free choice of shape and surface structure, such as patterns, grains or smooth surfaces. During injection molding, the machine liquefies or plastifies the thermoplastic material and injects it under pressure into a mould. Due to cooling, the plastic solidifies and can be removed from the mould after opening. Long-fiber-reinforced thermoplastics as granules are particularly suitable for injection moulding.

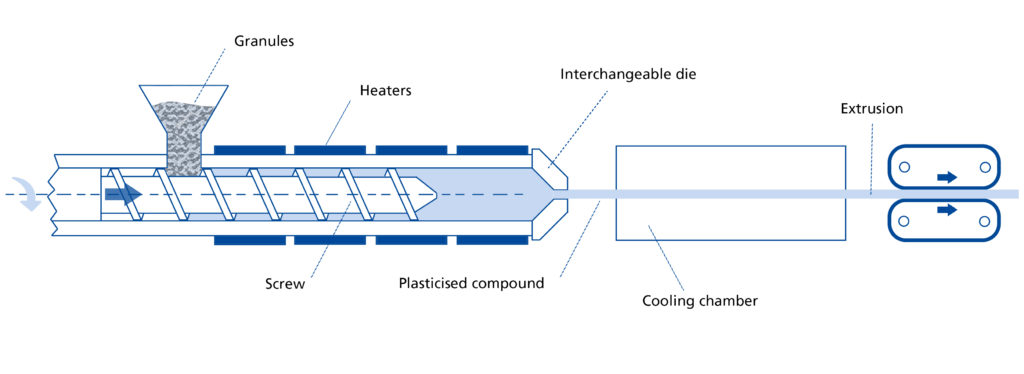

During extrusion, plastics are continuously melted and pressed as a viscous mass from a pressure chamber through a shaping die. The moulding compound is granulate or powder, which is plasticized and compacted. The finished pressed part is endless and is cooled in the next step by water or air so that the mould hardens. The extrusion process is frequently used for pipes, sheets and films. Window frames are also produced with this process.

Long fiber-reinforced thermoplastics are particularly suitable for this process.

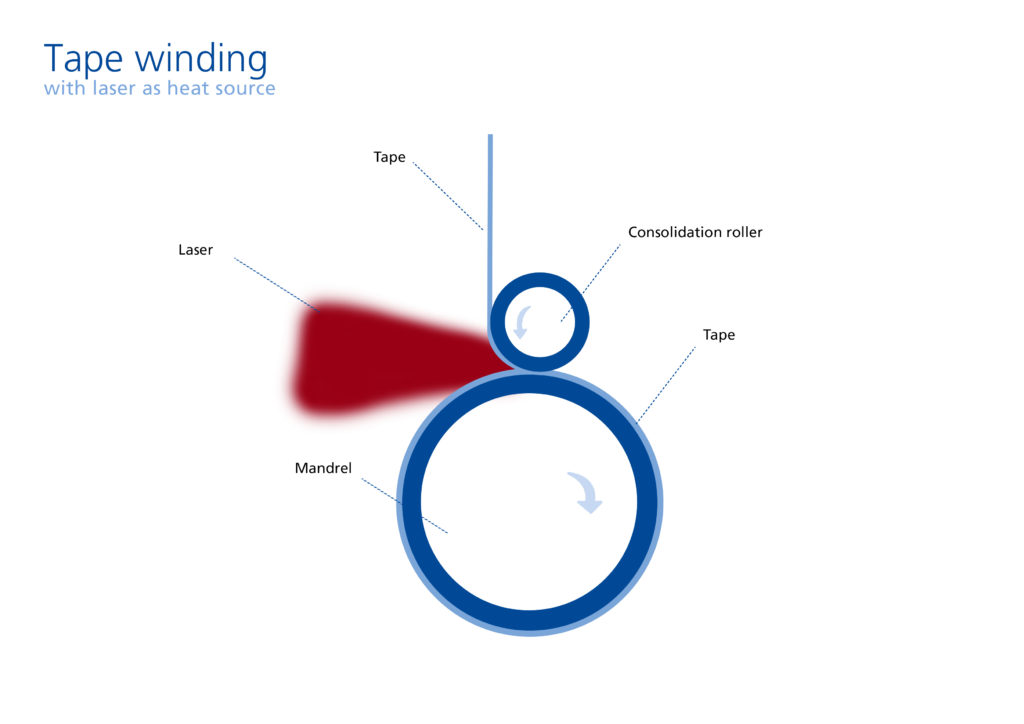

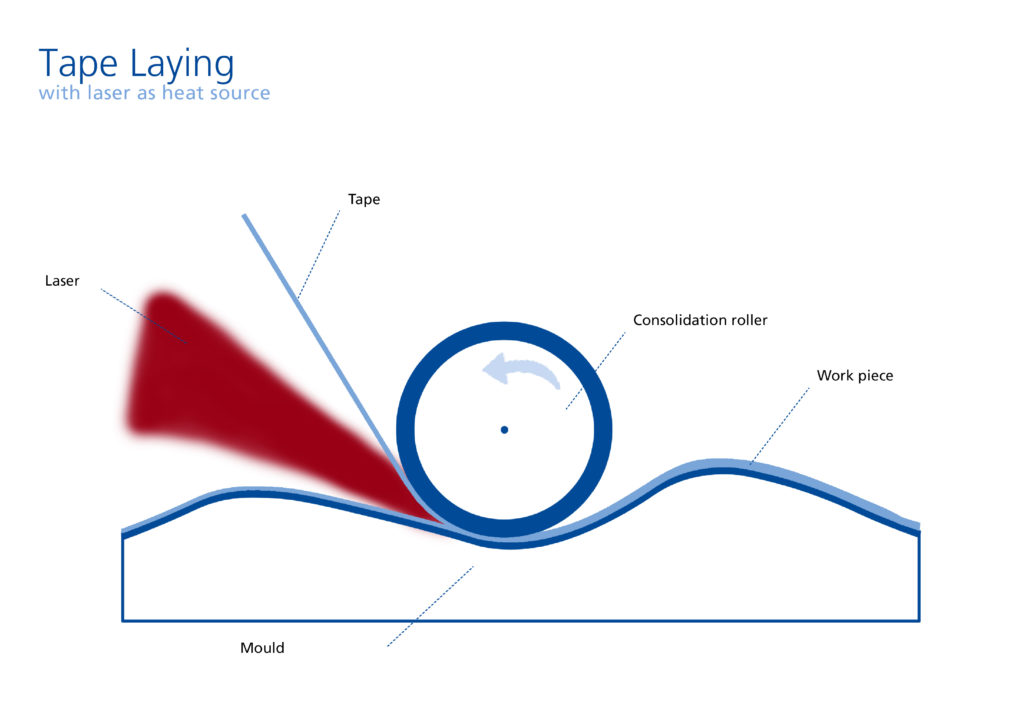

The laser-supported tape laying or winding is used to manufacture high-performance lightweight components such as aircraft wings. These processes are regarded as a promising option for processing endless fibre-reinforced thermoplastics. Unidirectional tapes, so-called UD tapes, are generally used in the tape laying process. UD tapes are endless fibre-reinforced tapes of different widths with unidirectionally aligned reinforcing fibres in which glass or carbon fibres are embedded so ideally in a thermoplastic matrix that completely new possibilities arise in the production of components.

At first, the tape is pushed forward below the consolidation unit. The laser radiation melts the thermoplastic matrix systems of the tape and the previously placed tape layers (substrate). During this the UD tape is traversed or lowered with the aid of a consolidation roller and pressed onto the substrate so that the thermoplastic melts bond together.

Now there are differences in the further procedure, because during tape laying, the connected thermoplastics are guided over the tool mould in a load-adapted path. On the other hand at the tapewinding process, it moves around a winding core. The UD tape strips away from a supply spindle and is welded to the already processed tapes by continuous laser irradiation.

The winding process is particularly suitable for the production of complex three-dimensional components such as tanks.

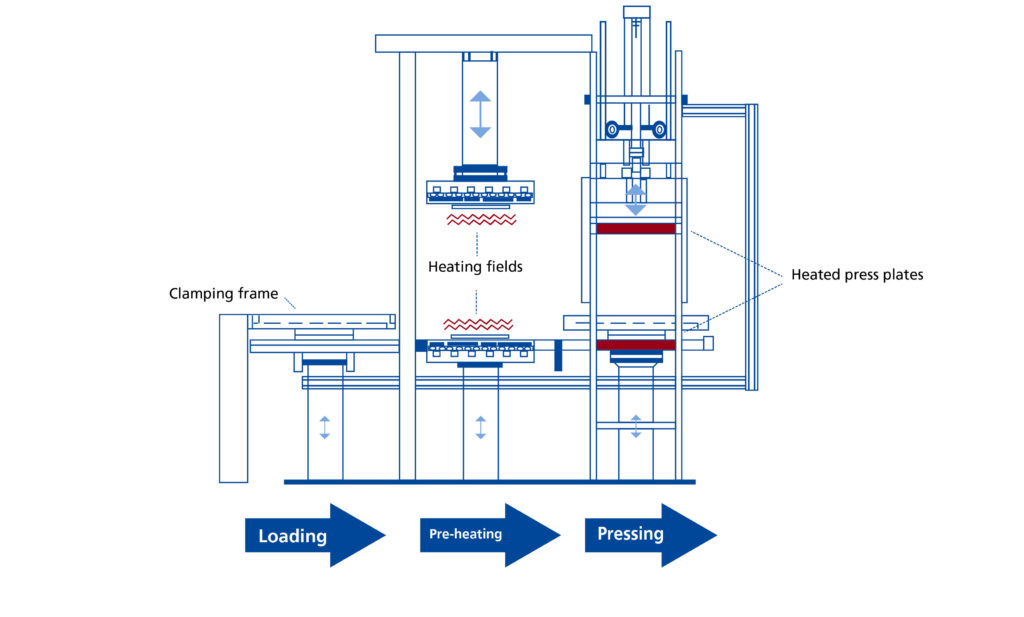

There are many different methods for part production in the field of thermoforming, for example with the help of vacuum, compressed air or a hydraulic press. For these methods, the material used, which is often fibre-reinforced, is differentiated as follows: Thinner semi-finished products are called foils, thicker semi-finished products are called laminates or organic sheets.

First, the semi-finished product is heated from one or both sides (depending on the process) in a heating station with a radiant heater. This softens the material and it is slightly pulled apart by a fixation device to prevent sagging. The heated material is held in place in a a clamping frame.

In thermoforming by hydraulic heating presses, the mouldable semi-finished product is moved into a forming tool with a positive and negative stamp. Then, it is pressed into the respective shape, cooled down and removed.

Finally, the finished workpiece is machined by means of a punch, for example, to add holes or to finish the edges. The thermoforming process is characterised by very short production times of up to less than one minute per component with high reproducibility. It is also very easy to automate, making it particularly suitable for large quantities. The other methods, such as the vacuum process, are similar, except that the forming process uses a vacuum to draw the heated material into the desired shape

Are you interested in UD Tapes, fiber reinforced laminates, long fiber reinforced thermoplastics (LFT), yarns and chopped cellulose or woven fibers?