The question about how to make a plastic component even more cost-efficient and how to achieve a higher lightweight potential is one that is being asked all over the entire automotive industry. The overmoulding process is known in many areas of application, but is not spread widely yet.

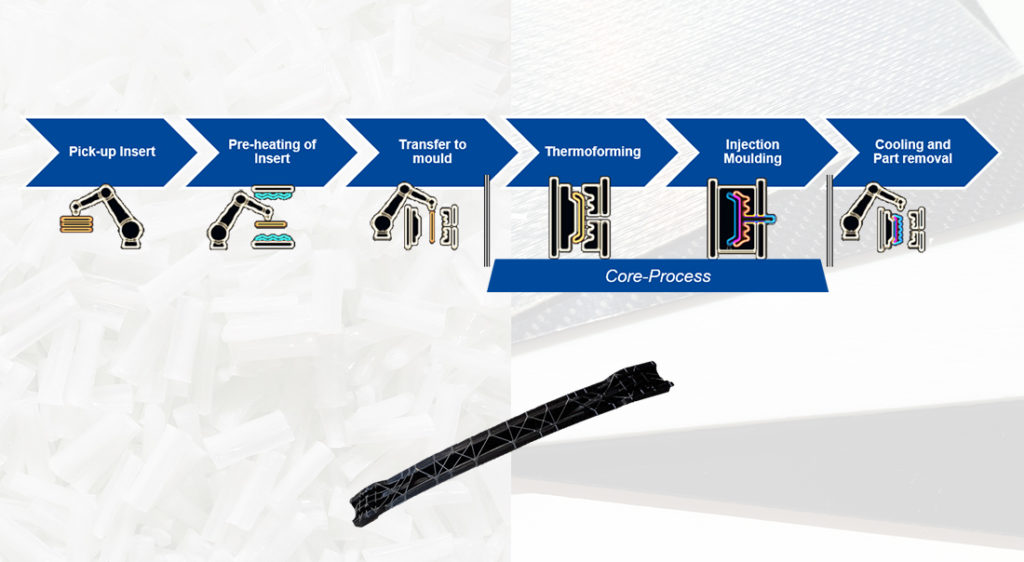

The technology implies a multi-component process in the manufacturing of plastic parts and involves combining the technologically mature process of injection moulding with thermoforming of fibre reinforced sheets which are used as insert material.

The advantage: The total costs can be optimized by this process solution. Due to the injected plastificate, no final contour machining is necessary, which in turn ensures shorter process times and thus creates an economic advantage. The plastic part also becomes more resistant and more impermeable to water. In terms of composition, the final component can have different textures and good insulating properties.

Since lightweight construction or weight reductions are one of the greatest challenges to be faced by the automotive industry, this is a promising process. Applications, such as the rear floor structure, can provide material and process advantages by using injection moulding of long fibre reinforced thermoplastics (LFT) in combination with thermoforming of unidirectional tapes (UD tapes) as well as fibre reinforced laminates. The result is total freedom in the part design giving high stiffness and strength for structural applications. The targeted use of LFT to reinforce the tape structure and to avoid dents can reduce the wall thickness and thus the overall weight.

But the overmoulding process can also be used in other ways. Depending on the choice of plastics, the final components can consist of different colours, different plastics and thus different degrees of hardness. Examples of these applications can be found in several consumer products.

The overmoulding process is still quite unknown in the automotive industry. This is partly due to the low level of awareness of continuous fibre-reinforced materials, such as long-fibre-reinforced thermoplastics and unidirectional tapes. Furthermore, most companies show a lack of expertise and professional know-how for processing this kind of material combination.

[contact-form-7 id=”587″ title=”Kontaktformular 1″]